As building managers and commercial real estate managers seek to optimize their operations and provide the most efficient services possible, they often turn to people counting technology to track foot traffic or gain occupancy insights.

While some of these options rely on cameras and facial recognition, others use Time-of-Flight (ToF) technology, which is personal privacy-respecting. This article will take a closer look at how Time-of-Flight technology works and why it is an effective means of counting people without intruding on an individual’s privacy or private data.

How does Time-of-Flight technology work?

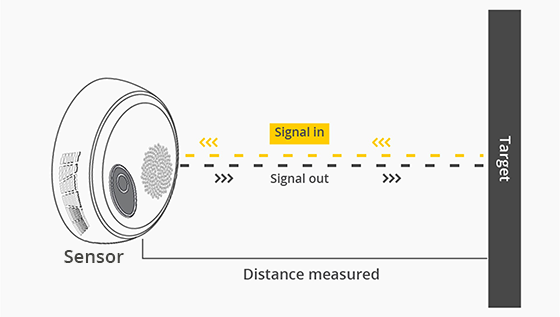

Time-of-Flight technology works by emitting a beam of light, typically in the form of infrared (IR) or laser pulses. The time it takes for the beam light to travel to an object and back again is measured. By calculating the time-of-flight of each pulse, ToF sensors can create a depth map of the surrounding environment and detect objects within it, including people.

The principle behind Time-of-Flight technology is similar to that of radar or sonar. However the key difference is that ToF uses light instead of sound or radio waves. As a result, Time-of-Flight sensors are more accurate than other distance measurement technologies. Additionally, ToF sensors are less sensitive to low light conditions, ambient noise and interference, making them suitable for use in a wide range of environments.

The result: anonymous People Counting data

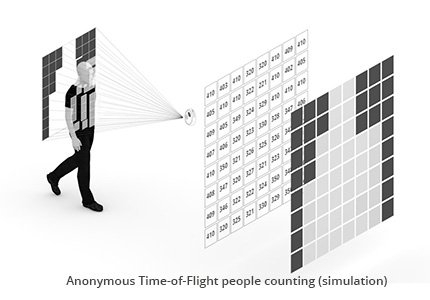

When Time-of-Flight technology is used in Smart Buildings for occupancy monitoring or people counting, it works in a completely non-camera, non-intrusive, anonymous way. Terabee people counting sensors, based on Time-of-Flight technology cannot capture any personal data, images or videos of individuals as they don’t use camera technology. Rather, Time-of-Flight technology simply detects presence and movements within a defined area.

Moreover, Terabee ToF sensors do not rely on capturing images, which is a key difference from camera-based technologies. They gather data related to three points when someone passes into the people counting area: head and both shoulders, nothing more. Terabee people counters don’t measure the height of someone passing into or out of the counting area, nor do they gather any information about gender, physical appearance, clothing or other personal data.

Individuals' privacy must be protected

Camera-based people counting technology relies on images or video footage, which may include personal identifiable information (PII) such as faces or clothing. This data can be sensitive and must be carefully handled to ensure that individuals’ privacy is protected.

While camera-based people counting technology can be effective in counting people and collecting data on their movements, it raises significant privacy concerns. Cameras record video footage of individuals, which can include personally identifiable information such as faces, clothing, and other distinguishing features. This data can be sensitive and may be used to identify individuals, which is a clear violation of their privacy.

To mitigate these privacy concerns, camera-based people counting technology must be designed and implemented with privacy in mind. This typically involves a process of data anonymization, which removes or obscures any personally identifiable information from the data collected by the cameras. However, even with anonymization, there is always a risk that the data may be de-anonymized or used in unintended ways, which can result in harm to individuals or groups.

An accurate, anonymous solution

Time-of-Flight technology is an effective means of counting people without intruding on their privacy or private data. Time-of-Flight sensors from Terabee don’t contain a camera or camera technology, so they do not recognize faces or track individuals’ movements. With ToF technology, individuals can move freely through monitored areas without fear of being tracked or monitored. And because only anonymous data is ever collected, the privacy of individuals is always protected.

As such, ToF technology is a valuable tool for businesses and organizations looking to monitor occupancy levels, foot traffic and improve the customer experience, without compromising individual privacy or data protection. This makes ToF technology ideal for use in public spaces and businesses, where people counting can help optimize operations and enhance customer experiences.

People Counting solutions from Terabee

As Time-of-Flight sensors only detect the presence of objects and do not capture images, video or audio, they do not collect any personal data.

The signals that these sensors use are fully anonymous and cannot be linked to a specific individual. Therefore, Terabee ToF technology enables people counting without infringing privacy rights. It also fully respects data protection regulations, by the very nature of the tech that is used.

Building managers need to consider the privacy implications of people counting technology carefully and choose technologies that respect individuals’ privacy and anonymity.

With its ability to aggregate data taken from up to five separate sensors, the People Counting L-XL device offers easy installation and configuration. It is a highly accurate solution to gather data on people flow at large doors, entrances and indoor gates, such as university auditoriums and large lecture theatres. On the other hand, the People Counting M device is suitable for standard doors and narrow corridors, such as in meeting rooms and washrooms.

Integration with existing systems

Terabee people counters are designed to seamlessly integrate with existing infrastructure and systems, making implementation straightforward for educational facilities. Whether it be integrating with access control systems, building management systems, or data analytics platforms, these counters offer compatibility and flexibility, allowing universities to leverage existing investments while enhancing their operational capabilities.

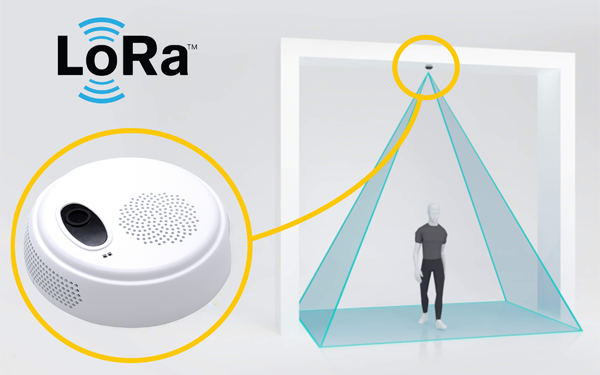

The People Flow Counting L-XL LoRa and People Flow Counting M 2.0 LoRa devices use LoRaWAN, which eliminates the need to install PoE cables or connect to the main IT system. This makes them ideal sensors for historic buildings which can be common in universities. The LoRa-enabled solution avoids the need to retrofit Ethernet cabling, which can be both expensive and time-consuming.